-

Jan, Thu, 2026

Modern Glass & Aluminum Solutions for Homes & Businesses in Wynwood

Wynwood is Miami’s most creative and design-forward district, defined by adaptive reuse, contemporary residential projects, galleries, studios, and high-visibility retail.

In a neighborhood where architecture, art, and brand identity intersect, projects demand glass and aluminum systems that deliver visual impact, durability, and performance.

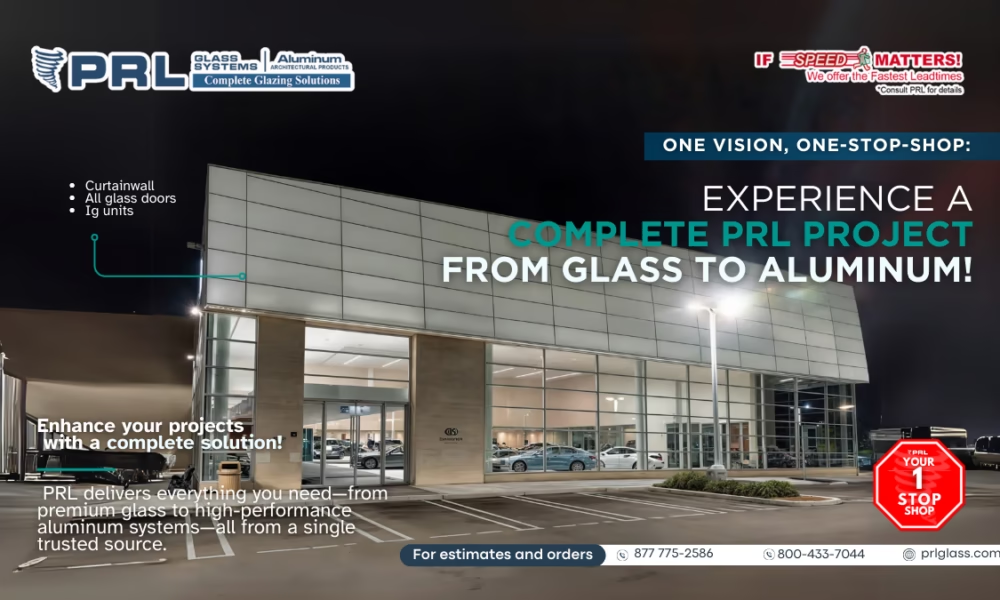

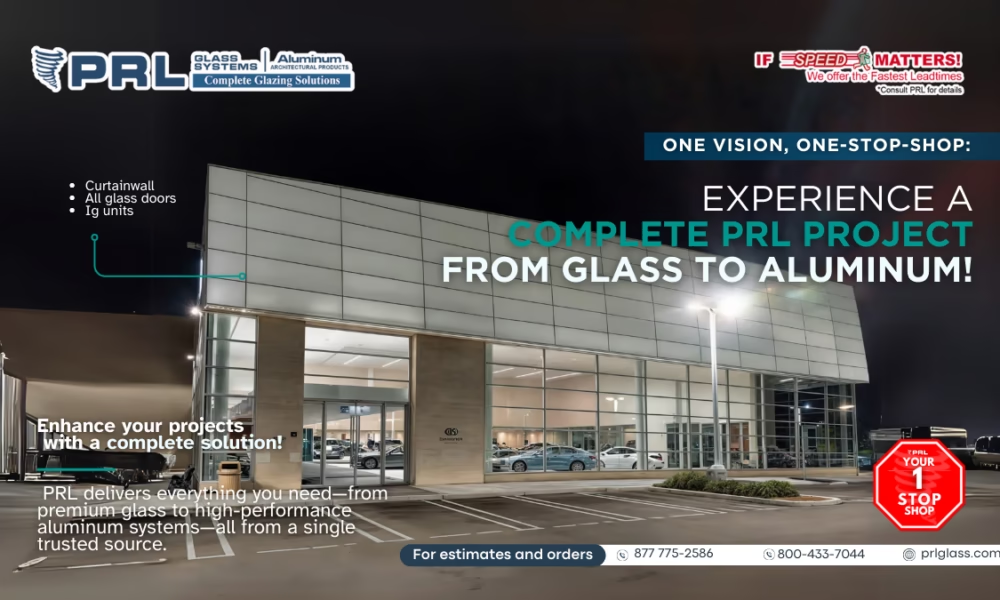

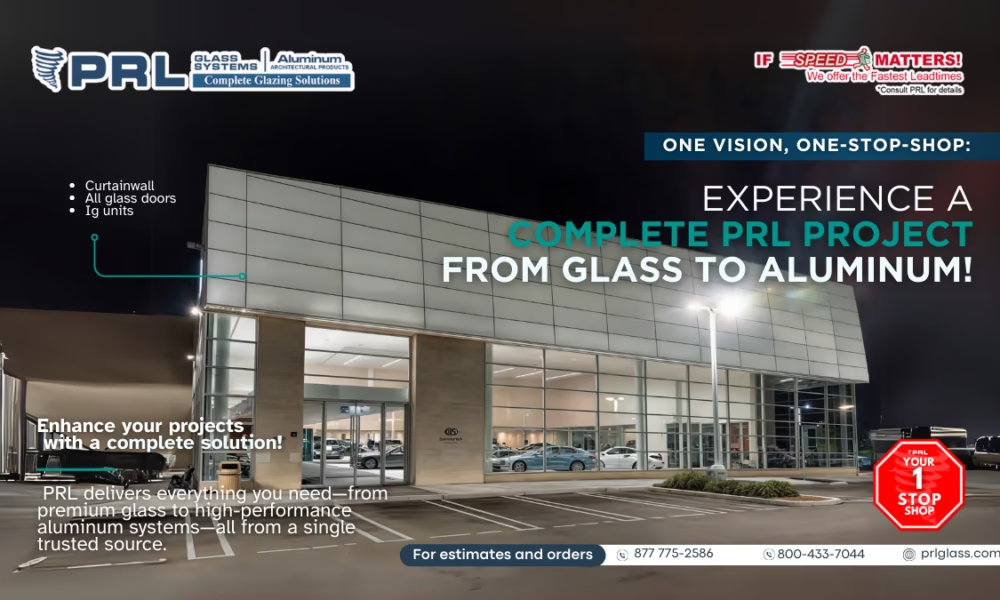

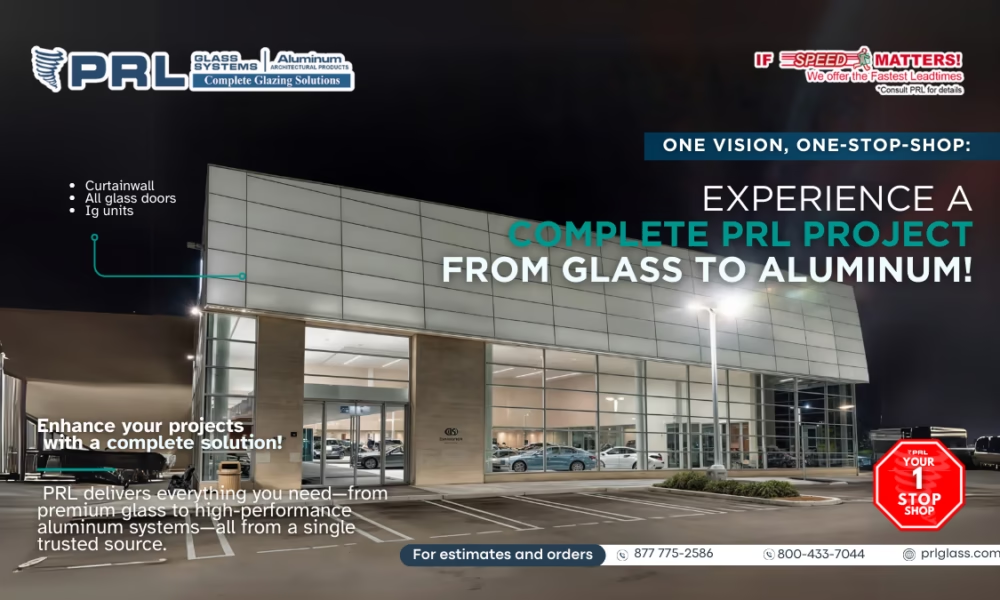

At PRL Glass & Aluminum, we provide modern architectural solutions tailored to Wynwood’s dynamic environment, supporting residential lofts, boutique commercial spaces, and creative workplaces with premium finishes and engineered reliability.

Building or Renovating in Wynwood? Connect with PRL Glass & Aluminum Today

Whether you’re transforming an industrial space into modern lofts, designing a gallery or studio, or upgrading a street-facing retail façade, PRL delivers custom fabrication, nationwide logistics, and expert technical support from California.

We proudly support projects throughout Wynwood, Midtown Miami, Design District, and the greater Miami metro area.

Service | Contact Number |

Aluminum Division | 📞 877-775-2586 |

Glass Division | 📞 800-433-7044 |

📍 Visit our locations in City of Industry, California and explore our wide range of innovative, high-quality aluminum and glass solutions!

Premium Glass & Aluminum Designs for Wynwood Residences

Wynwood residential projects favor open layouts, natural light, and modern industrial aesthetics. PRL’s premium residential systems elevate these spaces while delivering long-term performance.

- Sliding Glass Doors: Large-format systems ideal for loft-style living and indoor–outdoor transitions

- Residential Aluminum Doors: Clean, modern profiles designed for durability and security

- Glass Handrails: Minimalist solutions for staircases, balconies, and mezzanines

- Luxury Shower Sliders: Frameless designs for modern, high-end bathrooms

- Custom Glass Table Tops: Custom-cut architectural glass for interior design and creative spaces

All residential systems meet ASTM and NFRC standards, ensuring top-tier durability and performance for upscale Manhattan homes.

Glass & Aluminum Solutions for Wynwood Businesses

Wynwood’s commercial spaces, galleries, retail, hospitality, and creative offices, require architectural systems that combine branding, transparency, and resilience.

- Curtain Wall Systems: Ideal for mixed-use developments and modern commercial buildings

- Storefront Systems: Bold, clean façades for high-visibility retail and gallery spaces

Architectural Glass Solutions – Laminated and tempered glass for safety, acoustics, and solar control

PRL systems help businesses stand out while maintaining durability in a high-traffic, street-level environment.

Why Wynwood Developers and Homeowners Trust PRL Glass & Aluminum

In a neighborhood driven by design and transformation, PRL is trusted for flexibility, customization, and engineering expertise.

- Custom fabrication for adaptive reuse and modern new-build projects

- Large-format glazing and premium aluminum finishes

- Nationwide manufacturing with reliable lead times

- Technical support for architects, designers, developers, and builders

- Proven experience in creative, high-visibility environments

Benefits of Glass and Aluminum Systems in Wynwood

Wynwood architecture thrives on openness, transparency, and modern expression—glass and aluminum systems support this seamlessly.

- Thermal Performance for year-round comfort in residential and commercial spaces

- Noise Reduction, important in an active arts and nightlife district

- Modern Architectural Appeal aligned with industrial and contemporary aesthetics

- Durability suitable for high-traffic residential and commercial applications

- Eco-Friendly Materials, supporting LEED and sustainability-focused projects

- Battle Door Capability, offering reinforced security against break-ins, vandalism, or protests, especially critical for street-level retail, galleries, and studios

Transform Your Space with PRL Glass & Aluminum

Based in California and trusted nationwide, PRL serves Florida and all 50 states with luxury-grade architectural glass and aluminum systems.

From custom sliding doors to boutique storefronts, we deliver craftsmanship designed to elevate your next project.

We are present in the most important neighborhoods in the United States, offering the highest quality service.

✅ Brickell

Follow us on social media ✅

Stay tuned for news, events, discounts and new products through the different social media channels.