- MY ACCOUNT

- PRODUCT LINES

- ACCORDION BIFOLD

- ALL GLASS ENTRANCE DOOR

- ALUMINUM DOOR

- COUNTURED SLIDER

- CURTAINWALL

- FULL FRAME CLADDED DOOR

- GLASS SELECTION

- HANDRAILS

- INSULATED GLASS

- LAMINATED GLASS

- MAX SLIDER

- MIRROR

- PANIC DEVICE

- RUBY SLIDER

- SHOWER SLIDER

- SHOWER DOORS

- SANDBLAST

- STOREFRONT

- SPANDREL GLASS

- TIFFANY SLIDING DOOR

- TABLE TOP

- TECHNICAL DETAILS

- CATALOGS

- SHOP ONLINE

- PRL PRESS

- CONTACT US

SOUND CONTROL LAMINATED GLASS

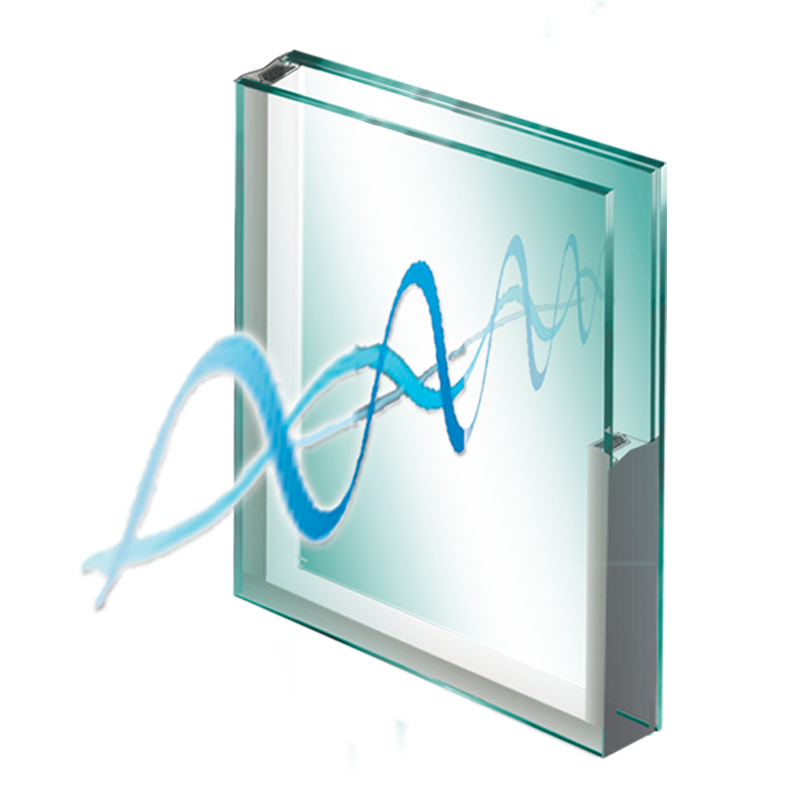

PRL’s sound control laminated glass is detail manufactured with a special acoustic grade PVB interlayer. This unique interlayer has advanced technology for high-grade acoustic control. When used with multiple IG unit combinations, extraordinary sound reduction can be obtained.

SOUND CONTROL LAMINATED GLASS

Laminated glass is ideal for sound control and UV protection. Adding an interlayer between the glasses provides an excellent barrier for noise and it also has additives that screen out damaging UV rays. Our 96” x 153” state-of-the-art lamination line can fabricate sound control glass with interlayers up to 3” overall thicknesses.

At PRL, we have an in-house lamination line so we’re able to produce custom laminated glass with the fastest lead-times in the industry! Laminated glass is another option when safety glass is required. It can be manufactured using glass that’s annealed, heat-strengthened or tempered and can be made up using different glass types including tinted, reflected, patterned or mirrored.

Get Solar Data

Laminated glass is produced by bonding layers of glass under pressure and heat, with a layer of film- called the interlayer, between them. This interlayer absorbs energy impacts and allows the sheet to flex and bend as a whole. Although the glass may break, its fragments remain firmly bonded to the interlayer, minimizing the risk of injuries to people or objects.

Learn More About Our Laminated Glass!

KNOW OUR LAMINATED PRODUCTS