- MY ACCOUNT

- PRODUCT LINES

- ACCORDION BIFOLD

- ALL GLASS ENTRANCE DOOR

- ALUMINUM DOOR

- COUNTURED SLIDER

- CURTAINWALL

- FULL FRAME CLADDED DOOR

- GLASS SELECTION

- HANDRAILS

- INSULATED GLASS

- LAMINATED GLASS

- MAX SLIDER

- MIRROR

- PANIC DEVICE

- RUBY SLIDER

- SHOWER SLIDER

- SHOWER DOORS

- SANDBLAST

- STOREFRONT

- SPANDREL GLASS

- TIFFANY SLIDING DOOR

- TABLE TOP

- TECHNICAL DETAILS

- CATALOGS

- SHOP ONLINE

- PRL PRESS

- CONTACT US

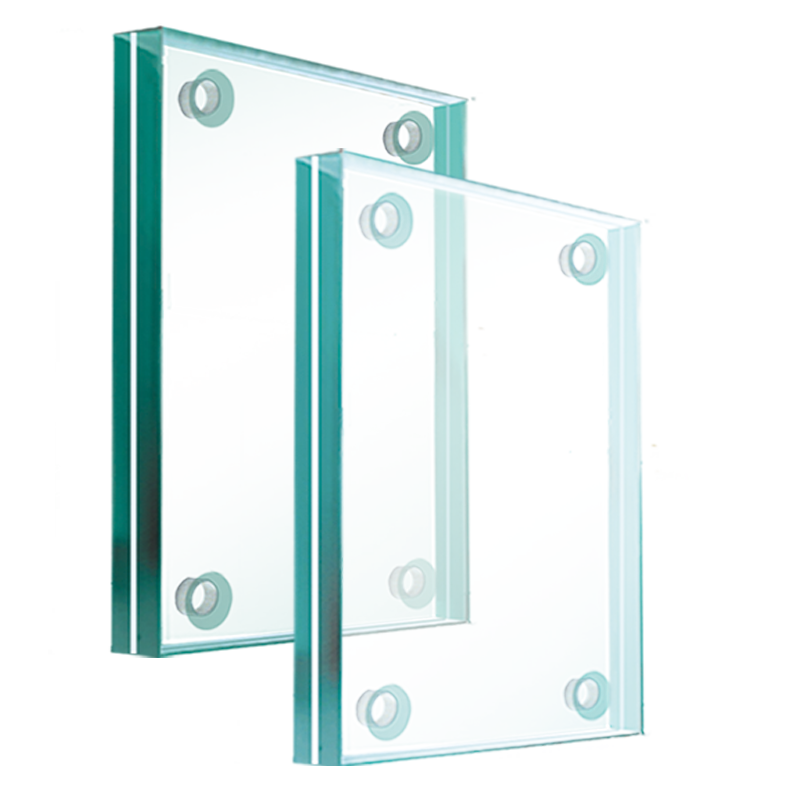

Laminated SentryGlas®

SENTRY GLAS®

SENTRYGLAS®

PRL offers laminated SentryGlas® for a wide range of projects. 5 times stronger and 100 times more rigid than traditional PVB’s, this structural interlayer delivers superior post-breakage stability that creates a lighter and safer alternative to withstand greater loads and higher threat levels. Sold in clear and translucent white interlayers, laminated SentryGlas® is also less susceptible to moisture intrusion and weathering effects when laminated glass edges are exposed.

At PRL, we have an in-house lamination line so we’re able to produce custom laminated glass with the fastest lead-times in the industry! Laminated glass is another option when safety glass is required. It can be manufactured using glass that’s annealed, heat-strengthened or tempered and can be made up using different glass types including tinted, reflected, patterned or mirrored.

Laminated glass is produced by bonding layers of glass under pressure and heat, with a layer of film- called the interlayer, between them. This interlayer absorbs energy impacts and allows the sheet to flex and bend as a whole. Although the glass may break, its fragments remain firmly bonded to the interlayer, minimizing the risk of injuries to people or objects.

Learn More About Our Laminated Glass!

KNOW OUR LAMINATED PRODUCTS