-

Aug, Wed, 2025

Bulletproof Glass Protection Levels According to NIJ Standards

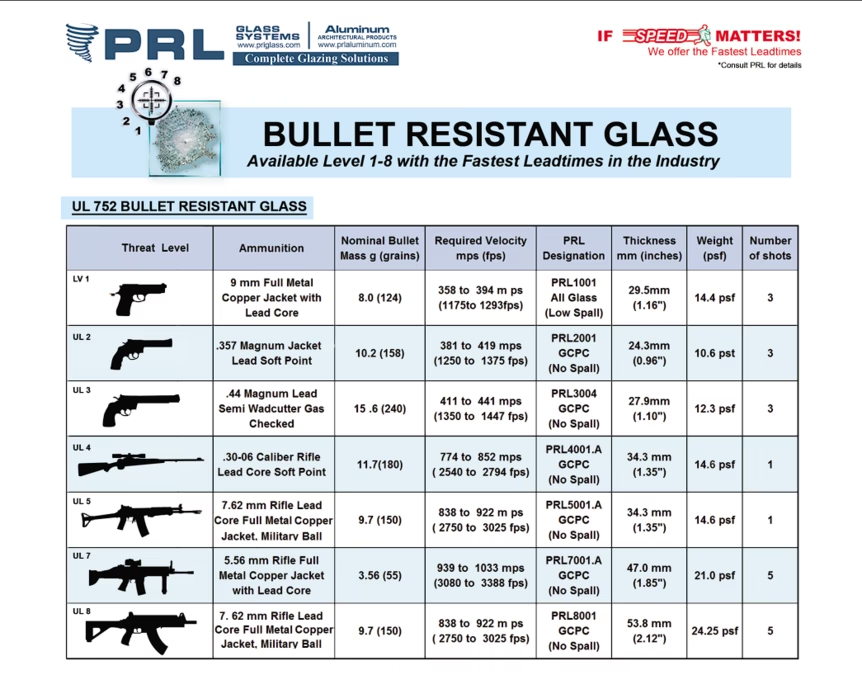

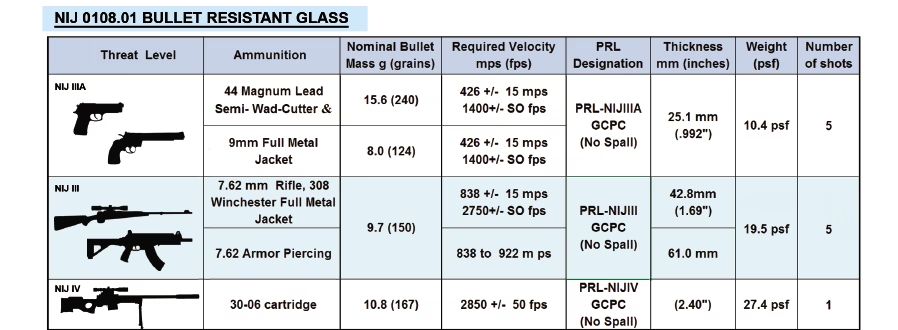

The NIJ (National Institute of Justice) standard is widely recognized in the field of ballistic protection, particularly for mobile and personal applications such as body armor, armored vehicles, and security booths.

Unlike the UL 752 standard (explained here), which focuses on construction and architectural applications, the NIJ standard is designed for materials that must respond to threats in dynamic environments.

The NIJ classification includes four ballistic protection level, each tested with specific ammunition types and impact velocities.

In this article, we will examine the four most relevant NIJ levels, explaining what each one entails and the most common use cases for them.

What Is the NIJ Classification?

The NIJ classification is a system developed by the National Institute of Justice in the United States to establish standards for ballistic resistance. Its purpose is to ensure that protective materials and equipment meet specific performance levels against different types of threats.

Unlike other standards, the NIJ system is primarily designed for personal protective equipment and mobile solutions, although it is also applied to ballistic glass and materials for vehicles, guard booths, sentry posts, and security cabins.

Each NIJ level is tested with specific firearms, calibers, and velocities under controlled conditions that simulate real-world attack scenarios. This allows manufacturers, distributors, and clients to reliably compare the protection level offered by each product.

In the case of bullet resistant glass, meeting an NIJ level means it has been engineered and tested to stop specific ballistic threats, from handguns to high-powered rifles, depending on the level.

NIJ Protection Levels

The NIJ standard defines five main levels of ballistic resistance, each tested with specific firearms, calibers, and velocities. Below, we explain what each level entails and its most common applications.

NIJ IIA – Basic and Concealable Protection

- Standard threat: 9 mm pistols and .40 S&W.

- Common use: lightweight vests, personal protection in low-risk environments.

- Advantages for homes or businesses: extremely lightweight and easy to conceal.

NIJ II – Lightweight Protection with Extended Coverage

- Standard threat: 9 mm pistols and .357 Magnum rounds fired from short-barrel handguns.

- Common use: personal protective vests, security booths, applications requiring discretion.

- Advantages for homes or businesses: greater protection than Level IIA without sacrificing lightness.

NIJ IIIA – Protection Against Large-Caliber Handguns

- Standard threat: high-caliber handguns such as .357 SIG and .44 Magnum.

- Common use: personal protection, civilian vehicles, security cabins in urban environments.

- Advantages for homes or businesses: lightweight and versatile protection, ideal for mobility.

NIJ III – Protection Against High-Powered Rifles

- Standard threat: 7.62 mm NATO (M80) rifle with soft-core projectile.

- Common use: armored vehicles, security facilities, checkpoints.

- Advantages for homes or businesses: stops standard rifle ammunition used in most assault rifles.

NIJ IV – Protection Against Armor-Piercing Ammunition

- Standard threat: .30-06 Springfield (AP) armor-piercing rounds and other high-penetration projectiles.

- Common use: military installations, high-risk government buildings, VIP transport.

- Advantages for homes or businesses: maximum protection level for civilian and strategic applications.

Levels such as RF2/RF3 (according to the most recent version of the standard) are designed for extreme ballistic threats and specialized military applications that exceed the protection range offered by any provider.

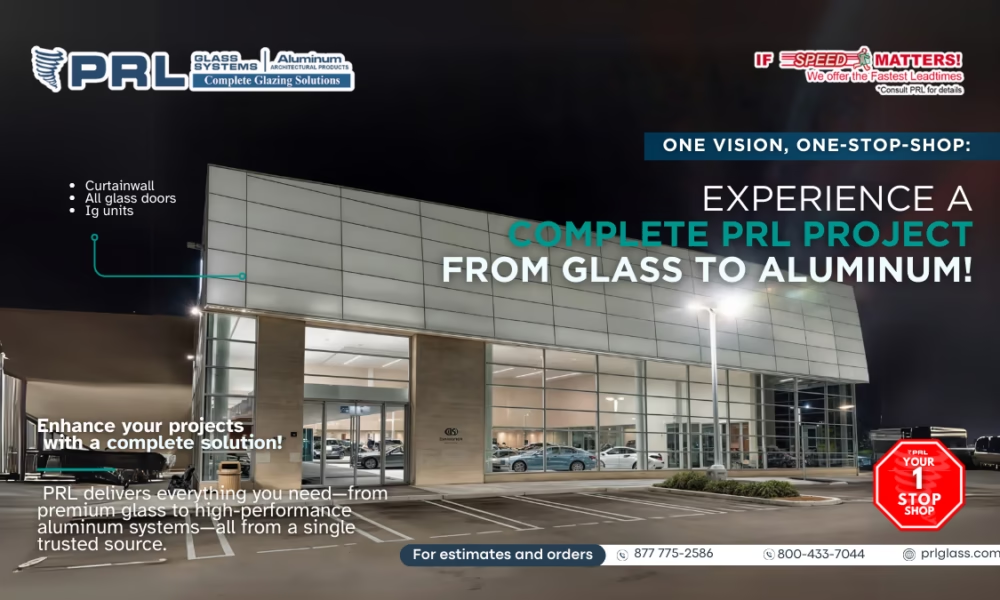

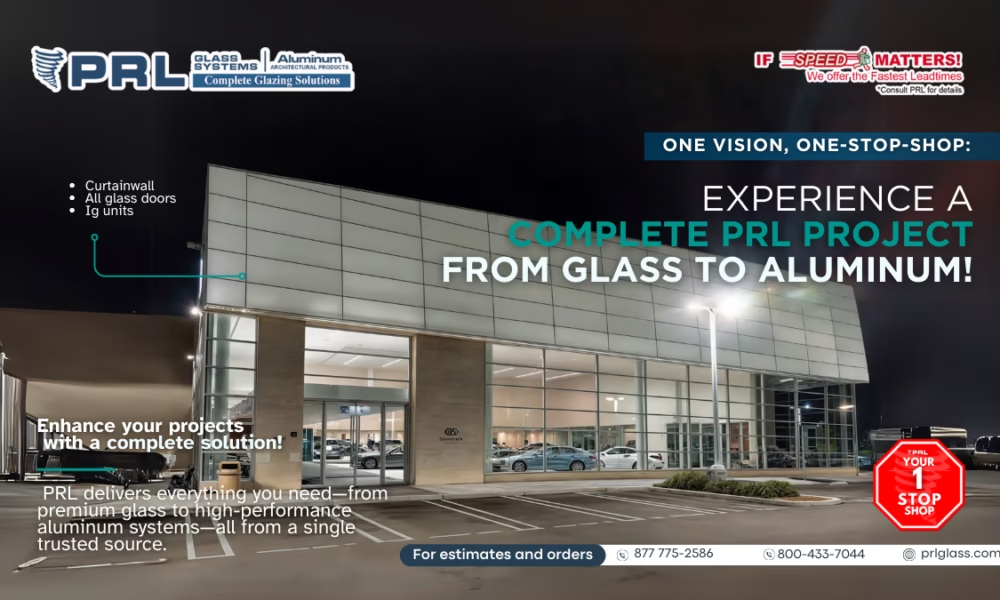

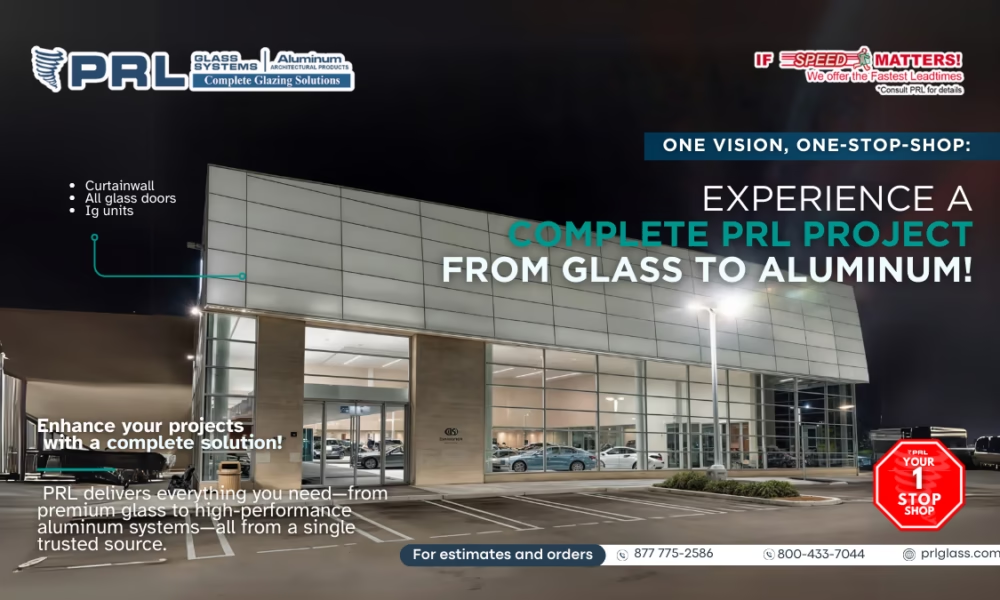

At PRL Glass & Aluminum, we work with NIJ Levels IIIA, III, and IV, covering a protection range from large-caliber handguns to armor-piercing ammunition used in military environments.

How to Choose the Right NIJ Level for Your Home or Business

Selecting the correct NIJ level is essential to ensure the necessary protection without generating unnecessary costs. The decision should be based on a realistic assessment of the most likely threats and the specific context where the glass or ballistic material will be installed.

Key factors to consider:

- Type of threat: handguns, high-powered rifles, or armor-piercing ammunition.

- Specific application: armored vehicle, security booth, corporate building, or military facility.

- Risk environment: areas with high crime rates, conflict zones, or low-risk urban environments.

- Mobility or fixed installation: higher levels may mean more weight, which is not always ideal for vehicles or lightweight structures.

- Regulatory compliance: some regulations require a minimum NIJ level for government or private security projects.

At PRL Glass & Aluminum, we help our clients determine the most appropriate NIJ level for their specific case, ensuring a balance between protection, functionality, and technical feasibility. For example:

✅ Residential or corporate in an urban area: NIJ IIIA

✅ Armored vehicles for executive transportation: NIJ III

✅ Critical security or high-risk facilities: NIJ IV

Understanding the NIJ protection levels is essential to selecting a solution that truly addresses the threats in your environment, without overspending. A proper assessment ensures that your choice of bullet resistant glass or ballistic material is efficient, functional, and compliant with the technical and regulatory requirements of your project.

At PRL Glass & Aluminum, we have the expertise, technical capabilities, and manufacturing capacity to deliver customized solutions that meet NIJ Levels IIIA, III, and IV. These levels cover everything from protection against large-caliber handguns to defense against armor-piercing ammunition used in high-risk environments.

If you are looking for guidance in defining the most suitable NIJ level for your home, business, or strategic facility, our team is ready to help you find the safest and most cost-effective option. Contact us today and let’s take your security to the next level.