-

Dec, Tue, 2025

Types of Low-E Glass: Hard Coat, Soft Coat & IGU Applications Explained

When people talk about low-E glass, it’s often presented as a single product. In practice, it’s not. There are different types of low-E coatings, each with distinct thermal benefits, solar control levels, and specific applications depending on climate, building type, and the window or façade system.

For architects, contractors, and specifiers, understanding these differences is essential to:

- Select the correct glass based on the expected performance

- Avoid over-specifying or under-specifying a system

- Optimize U-factors, SHGC, and overall indoor comfort

- Ensure compatibility with IGUs, laminated glass, and aluminum framing systems

- Technically justify specification decisions to clients or developers

In this article, we will clearly and technically explain:

- What hard coat low-E glass is

- What soft coat low-E glass is

- How low-E performs within an insulated glass unit (IGU)

- How to choose the right low-E type based on climate conditions

- How PRL works with these systems in real-world applications for windows, doors, and façades. The goal is not to promote one low-E type over another, but to help you specify the right solution based on the real performance requirements of each project.

What Is Hard Coat Low-E Glass?

Hard coat low-E, also known as pyrolytic low-E, is a type of low-emissivity coating that’s applied directly to the glass during the manufacturing process, while the glass is still hot on the float line.

Because of this process, the coating chemically fuses with the glass surface, resulting in an extremely durable and resistant layer.

Characteristics of Hard Coat Low-E

- Coating applied at high temperature (pyrolytic process)

- High mechanical and chemical durability

- Can be used as monolithic glass or integrated into an IGU

- Higher solar heat gain compared to soft coat low-E

- Low emissivity, though higher than soft coat low-E

In simple terms, hard coat low-E reduces heat loss while allowing more solar energy to enter the building.

Thermal Performance of Hard Coat Low-E

Hard coat low-E primarily works as an interior heat reflector:

- In winter, it reflects interior heat back into the space

- Reduces heat loss through the glass

- Takes advantage of direct solar radiation

For this reason, it’s often associated with projects where solar heat gain is desirable rather than blocked.

Typical Applications of Hard Coat Low-E

Hard coat low-E is a suitable option for:

- Cold climates with long heating seasons

- Residential buildings with high heating demand

- Projects that prioritize simplicity and coating durability

- Applications where the glass may be exposed before being assembled into an IGU

It’s also useful in projects where extreme solar control is not a priority, but basic energy efficiency and coating resistance are required.

Limitations of Hard Coat Low-E

Although it’s a reliable system, hard coat low-E has limitations when compared to soft coat low-E:

- Less effective solar heat control in warm climates

- Higher SHGC values

- Lower overall performance in mixed or high-solar radiation climates

- Doesn’t achieve the same energy efficiency levels as modern soft coat low-E within an IGU

For these reasons, its use today is more specific and climate-dependent, and it’s generally recommended only when the project conditions clearly justify it.

What Is Soft Coat Low-E Glass?

Soft coat low-E, also known as solar control low-E, is a low-emissivity coating applied to glass using an off-line process called Magnetron Sputter Vacuum Deposition (MSVD).

Unlike hard coat low-E, this coating is applied to cooled glass inside a vacuum chamber, allowing for much greater precision in thermal and solar performance control.

The result is a microscopic, highly efficient coating, engineered to maximize thermal insulation and solar control, especially when integrated into an insulated glass unit (IGU).

Key Characteristics of Soft Coat Low-E

- Cold-applied coating (MSVD process)

- Very low emissivity (significantly lower than hard coat)

- High control of infrared (IR) and ultraviolet (UV) radiation

- Must be protected within an IGU or laminated glass

- Excellent energy performance in mixed and warm climates

- Available in neutral, selective, or high solar-control versions

In simple terms: soft coat low-E not only reduces heat loss, but actively blocks unwanted heat gain, without sacrificing natural daylight.

Thermal and Solar Performance of Soft Coat Low-E

Soft coat low-E acts as a high-performance thermal barrier:

- In summer, it reflects a large portion of solar heat before it enters the interior

- In winter, it helps retain interior heat when combined with an IGU

- Significantly reduces the solar heat gain coefficient (SHGC)

- Substantially improves the overall U-factor of the glazing system

This balance makes it the most versatile low-E option for many contemporary projects in the United States.

Typical Applications of Soft Coat Low-E

Soft Coat Low-E is ideal for:

- Mixed climates (most of the U.S.)

- Warm or high solar-radiation regions

- Facades with large glass openings

- High-performance windows and doors

- Premium residential projects and commercial buildings

- Systems aiming to meet modern energy standards

For these reasons, soft coat low-E is the most widely used low-E coating in modern window systems today.

Important Considerations for Soft Coat Low-E

- Despite its superior performance, soft coat low-E requires specific conditions:

- Must be sealed within an IGU or laminated glass

- Not designed for prolonged direct exposure

- Requires controlled fabrication and handling

These requirements are not disadvantages, but rather part of its advanced design to achieve maximum energy performance and durability.

Low-E in IGU’s (Insulated Glass Units): Why It Maximizes Performance

The true potential of low-E glass is achieved when it is integrated into an insulated glass unit (IGU). While low-E coatings already improve the thermal performance of glass on their own, combining them with an air or gas-filled cavity transforms the system into a high-performance solution for modern windows, doors, and façades.

An IGU generally consists of:

- Two or more glass panes

- A sealed cavity between them (air or argon gas)

- A perimeter spacer

- Seals that ensure airtightness

When low-E is strategically positioned within this unit, thermal and energy performance are significantly enhanced.

Low-E Coating Placement Inside an IGU

In a standard double-pane IGU’s, there are four possible glass surfaces:

- Surface #1: Exterior face of the outer glass

- Surface #2: Interior face of the outer glass

- Surface #3: Exterior face of the inner glass

- Surface #4: Interior face of the inner glass

In most applications:

👉 Soft coat low-E is installed on surface #2 or #3, protected inside the sealed cavity.

This placement allows the coating to:

- Reflect solar heat before it enters the interior

- Retain interior heat during winter

- Remain protected from physical or environmental damage

Correct placement is critical to optimizing U-factors, SHGC, and overall indoor comfort.

How Low-E Works Inside an IGU

When low-E is part of an IGU, it:

- Reflects infrared radiation depending on the season

- Reduces heat transfer through conduction and radiation

- Works together with argon gas to minimize energy loss

- Maintains high visible light transmittance

The result is a system that doesn’t just block heat but actively manages the energy entering and leaving the building.

Key Benefits of Low-E + IGU’s

The low-E + IGU combination delivers:

- Significantly lower U-factors (better insulation)

- Controlled SHGC, ideal for warm or mixed climates

- Greater comfort near windows and large glazing areas

- Reduced load on HVAC systems

- Less condensation in cold climates

- Increased durability of the overall glazing system

For this reason, an IGU without low-E is now considered incomplete in modern architectural projects.

Low-E in IGU’s for Advanced Applications

In higher-performance projects, low-E within IGU’s can be combined with:

- Argon or krypton gas for enhanced insulation

- Laminated glass for safety, acoustic control, or impact resistance

- Selective low-E coatings for highly sun-exposed façades

- Triple-pane configurations for extreme climates

This flexibility allows glass performance to be tailored to the specific needs of each project, without compromising aesthetics or visual clarity.

Low-E glass reaches its maximum performance when it’s part of a well-designed IGU. It’s not just about the coating itself, but about the entire system working together as an intelligent thermal barrier.

That’s why, in contemporary architecture, specifying low-E + IGU’s is no longer a premium option. It’s a logical technical decision to achieve long-term efficiency, comfort, and durability.

- You may also be interested in reading: Low-E Glass vs Clear Glass: Real Performance Differences and When to Choose Each One

How to Choose the Right Low-E Glass Based on Climate

Choosing between hard coats, soft coats, or advanced IGU configurations should never be a cost-driven decision.

The real performance of low-E glass depends directly on climate, building orientation, opening sizes, and the project’s energy goals. For that reason, proper specification must always start with the climate.

Below is a practical guide to selecting the right low-E solution based on real project conditions.

Cold Climates (Long Winters and Low Solar Radiation)

👉 Primary goal: Retain interior heat and take advantage of passive solar gain.

Recommended configuration:

- Hard coat low-E

- Basic IGU (double pane)

- Medium–high SHGC

Why it works:

- Allows higher solar heat gain

- Reflects interior heat back into the living space

- Reduces heat loss without blocking useful solar radiation

Typical applications:

- Residential projects in northern cold regions

- Buildings with constant heating demand

- Projects where solar control is not a priority

Hot Climates or High Solar Radiation Areas

👉 Primary goal: Block heat gain and reduce air conditioning loads.

Recommended configuration:

- Soft coat low-E (solar control)

- IGU with argon gas

- Low SHGC

- High UV protection

Why it works:

- Reflects a large portion of solar heat before it enters the building

- Reduces interior overheating

- Improves comfort near windows and exposed façades

Typical applications:

- Desert or very sunny regions

- East or west-facing façades

- Projects with large, glazed openings

Mixed Climates (Most of the United States)

👉 Primary goal: Balance summer solar control with winter thermal insulation.

Recommended configuration:

- High-performance soft coat low-E

- Well-sealed IGU

- Medium–low SHGC

- Low U-factor

Why it works:

- Provides year-round thermal control

- Reduces both excessive heat gain and heat loss

- Most versatile and efficient long-term solution

Typical applications:

- Modern residential homes

- Commercial buildings

- New construction and energy-focused renovations

Coastal Zones or Severe Weather Conditions

👉 Primary goal: Combine energy efficiency with durability and resistance.

Recommended configuration:

- Soft coat low-E + IGU

- Laminated glass (impact / safety)

- Argon gas fill

- High-performance sealing systems

Why it works:

- Controls heat and solar radiation

- Improves acoustic insulation

- Adds structural resistance and extends system lifespan

Projects Requiring Maximum Visual Clarity or Premium Aesthetics

👉 Primary goal: Energy performance without compromising glass appearance.

Recommended configuration:

- Selective soft coat low-E

- High visible light transmittance (VLT)

- Neutral color tone

Why it works:

- Maintains clean, uniform façades

- Reduces excessive reflectivity

- Ideal for contemporary architecture and premium projects

Key Technical Recommendation

There is no single “universal” low-E solution that works equally well in every scenario. The best choice always comes from combining:

- Climate conditions

- Building orientation

- Size of glazed surfaces

- Energy and comfort objectives

- Budget and building life cycle

For this reason, in professional projects, low-E specification should be supported by technical expertise, not selected solely based on trends or initial cost.

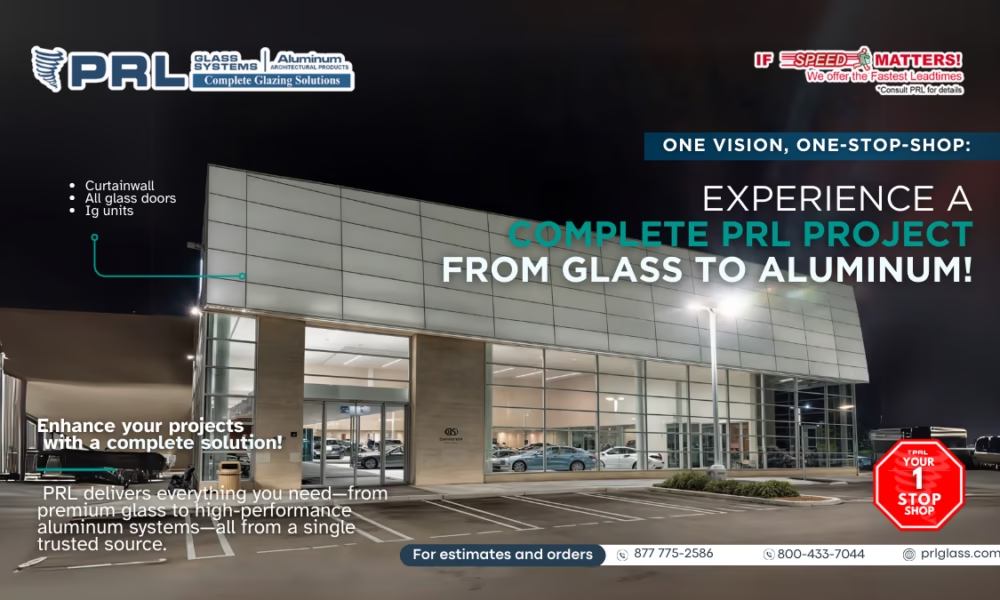

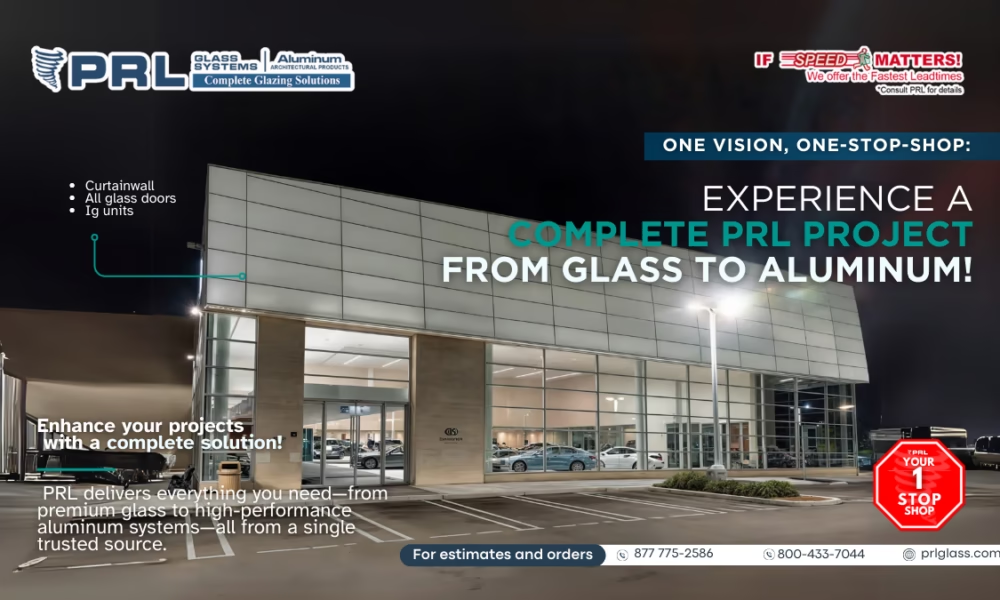

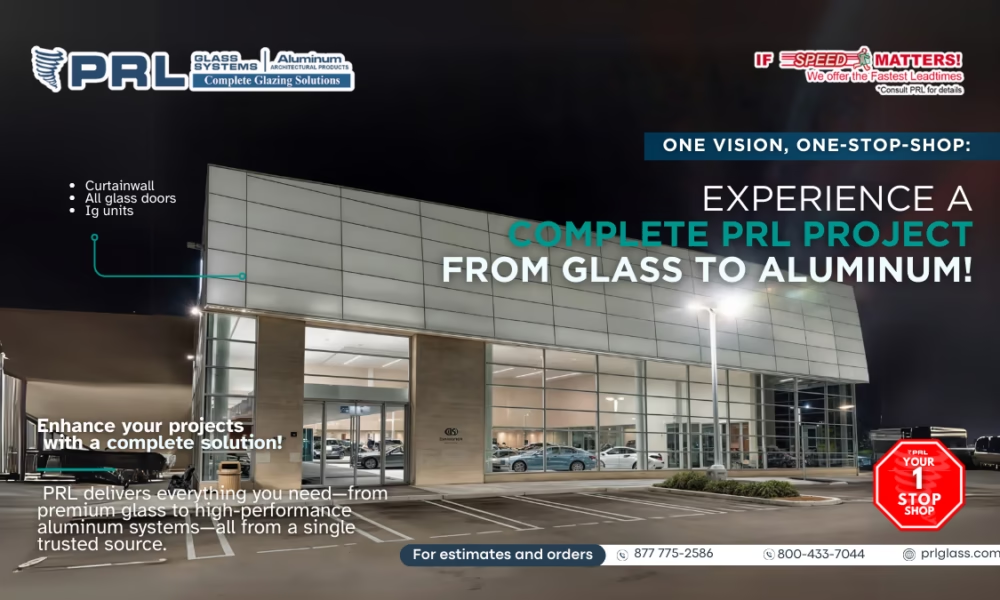

PRL’s Capabilities in Low-E Glass Manufacturing and System Specification

Specifying low-E glass correctly goes beyond selecting a coating type. Performance depends on how the glass is manufactured, integrated into the glazing system, and adapted to the project’s real conditions.

At PRL, low-E glass is treated as part of a complete architectural system, not as a standalone product.

PRL works with both passive (hard coat) and solar control (soft coat) low-E technologies, allowing each project to be specified based on climate, orientation, system type, and performance objectives rather than a one-size-fits-all solution.

Broad Low-E Options for Architectural Applications

PRL’s low-E glass options support a wide range of architectural needs, including:

- Solar Control Low-E: Designed to reduce solar heat gain in warm or high-radiation climates while maintaining high visible light transmission.

- Passive Low-E: Optimized for cold climates where heat retention and passive solar gain are priorities.

These options allow architects and engineers to balance U-factors, SHGC, visual clarity, and comfort depending on project requirements.

Compatibility with Advanced Glazing Systems

PRL’s low-E glass is fabricated to integrate seamlessly into high-performance glazing assemblies, including:

- Insulated glass units (IGUs) for improved thermal insulation

- Laminated glass for safety, acoustic control, or impact resistance

- Curtain wall systems, storefronts, and window or door applications

- Double-skin and point-supported curtain wall systems

Low-E coatings are properly protected within IGU’s or laminated assemblies to ensure long-term durability and consistent performance.

Multiple Thicknesses and Coating Technologies

PRL offers low-E glass in multiple thicknesses—1/8″ (3.2 mm), 3/16″ (5 mm), and 1/4″ (6 mm)—making it suitable for a wide variety of residential and commercial applications.

Available coating technologies include:

- Pyrolytic (hard coat) low-E, valued for durability and ease of handling

- MSVD (soft coat) low-E, offering superior solar control and lower emissivity

This flexibility allows PRL to support both straightforward applications and highly customized, performance-driven projects.

Technical Support for Proper Specification

One of PRL’s key strengths lies in supporting architects, contractors, and developers during the specification process. This includes:

- Guidance on selecting the correct low-E type based on climate and orientation

- Integration of low-E glass into IGU’s, laminated systems, and aluminum framing

- Assistance optimizing energy performance without compromising visual design

- Ensuring compatibility with local energy codes and performance expectations

Rather than promoting a single solution, PRL focuses on helping teams specify the right low-E configuration for each project, balancing efficiency, durability, aesthetics, and long-term value.

PRL’s low-E glass solutions are designed to deliver year-round efficiency, occupant comfort, and visual clarity. By combining coating technology, glass thickness, IGU configuration, and system integration, PRL ensures that low-E glass performs as intended, not just on paper, but in real architectural conditions.