-

Dec, Wed, 2025

Premium Glass & Aluminum Solutions for Sioux Falls

Sioux Falls is one of the fastest-growing metro areas in the Midwest, driven by strong development in healthcare, financial services, education, industrial facilities, and expanding residential communities.

Builders in South Dakota need durable, energy-efficient systems that perform in a climate with cold winters, hot summers, and strong winds.

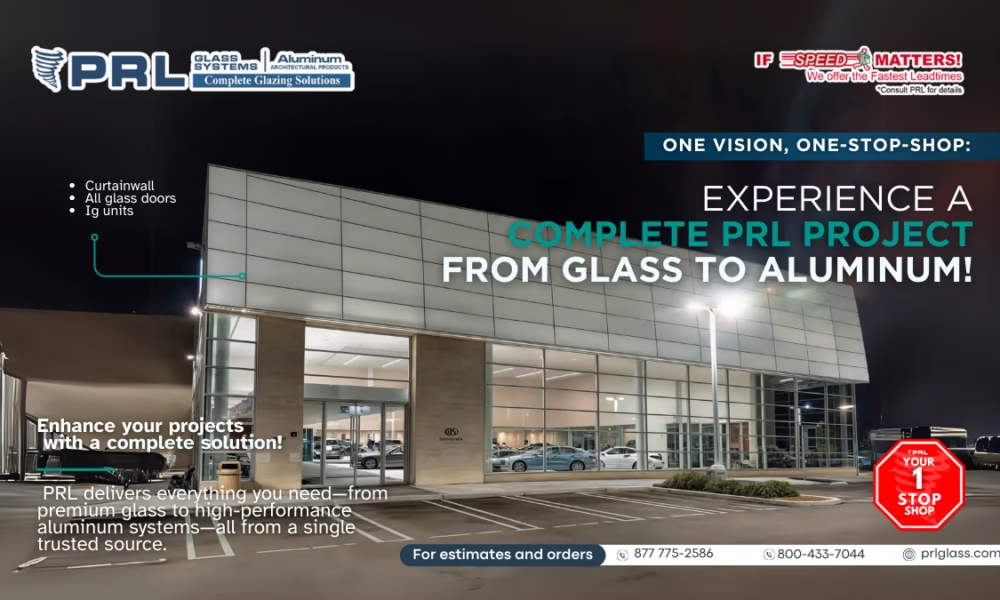

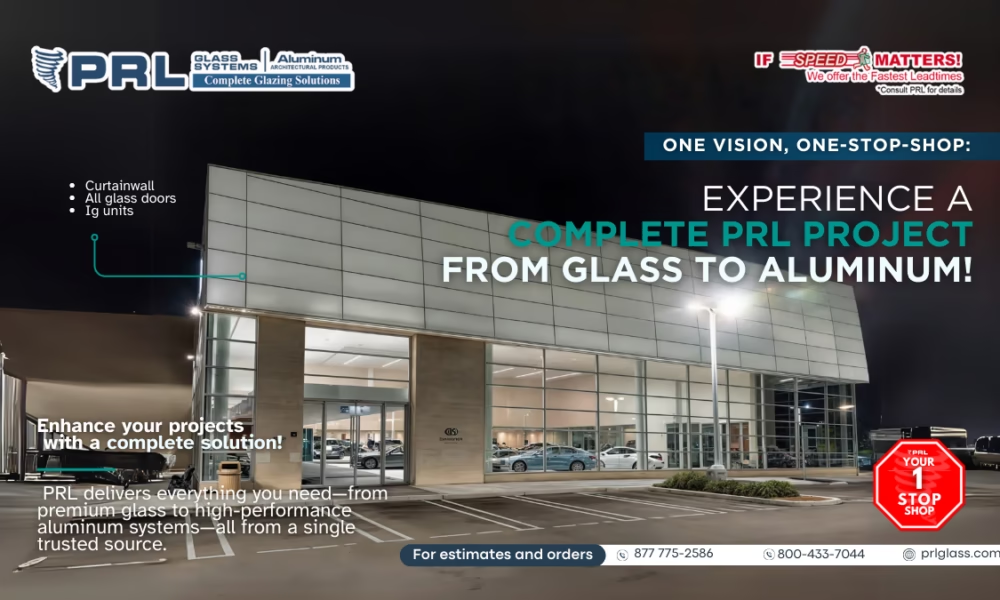

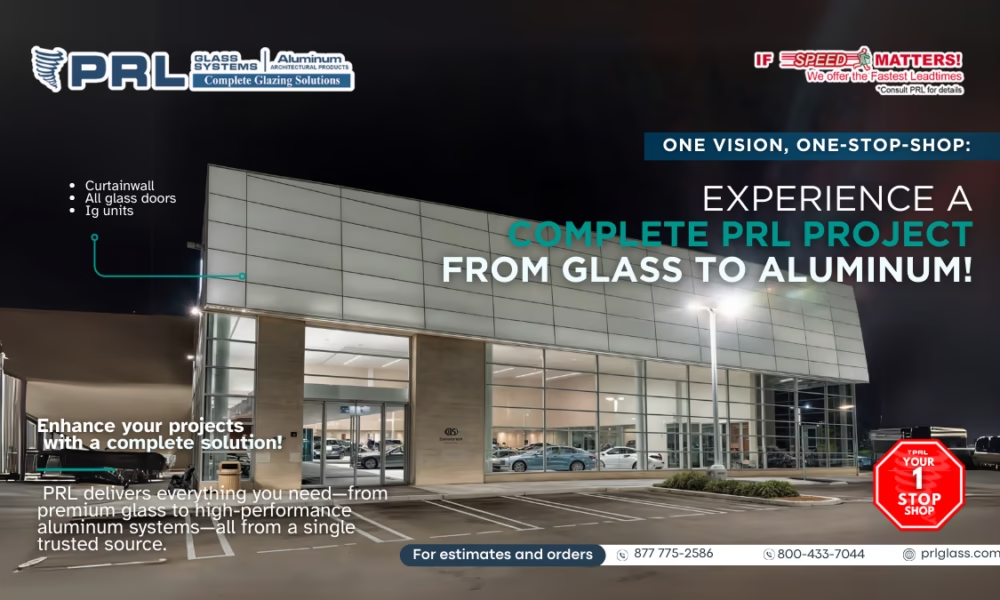

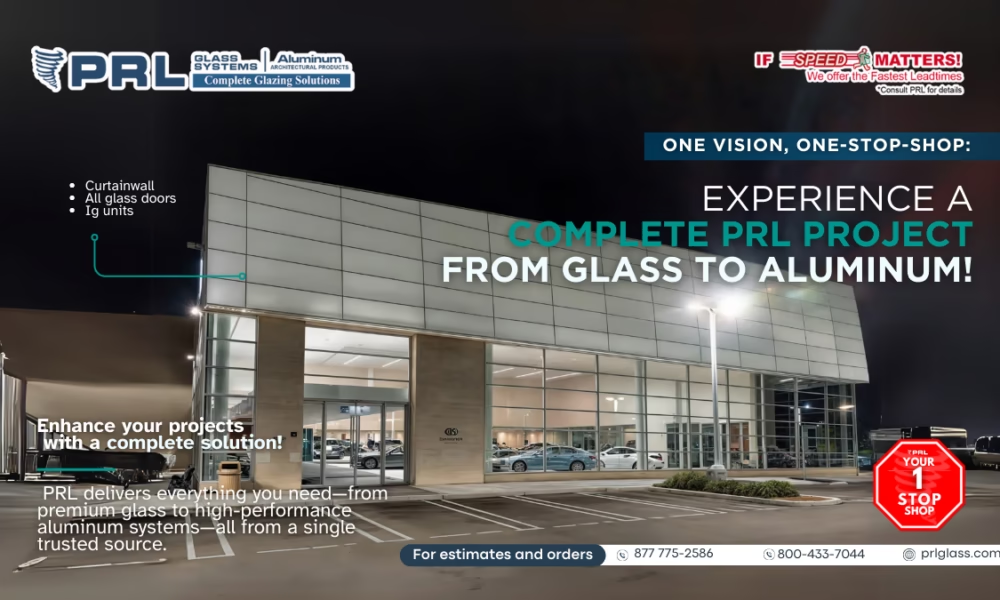

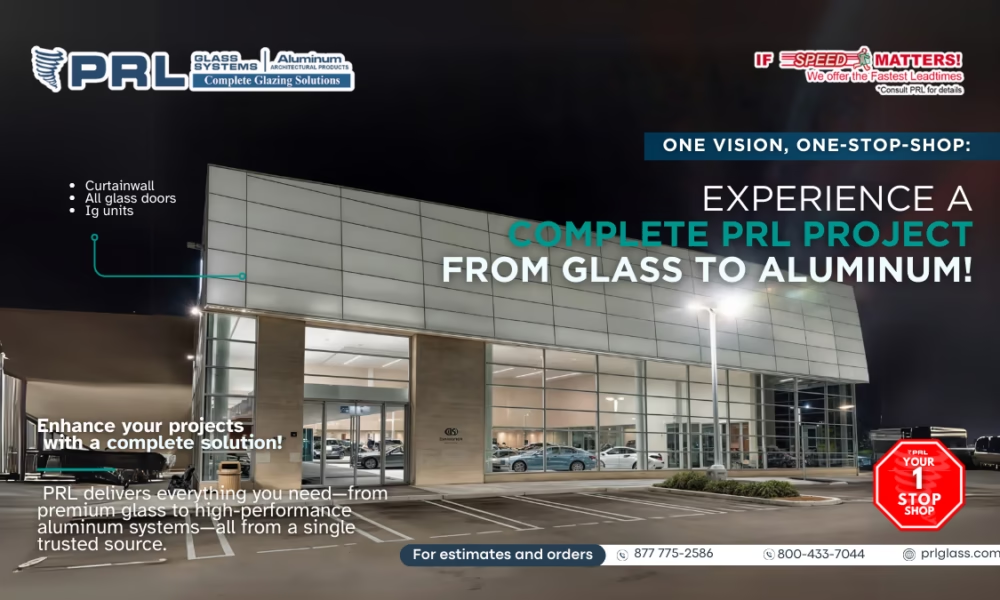

At PRL Glass & Aluminum, we manufacture high-performance glass and aluminum systems engineered for long-term reliability, ideal for commercial buildings, hospitals, universities, retail centers, and residential developments throughout South Dakota.

Building in Sioux Falls? Connect with PRL Glass & Aluminum Today

PRL supports Sioux Falls, area construction with fast nationwide shipping, custom fabrication, and expert project guidance.

We proudly serve Sioux Falls, Rapid City, Aberdeen, Brookings, and construction teams across South Dakota.

Service | Contact Number |

Aluminum Division | 📞 877-775-2586 |

Glass Division | 📞 800-433-7044 |

📍 Visit our locations in City of Industry, California and explore our wide range of innovative, high-quality aluminum and glass solutions!

Advanced Glass & Aluminum Designs for Sioux Falls Builders

Our systems are designed to meet South Dakota’s environmental demands, delivering strength, insulation, and modern architectural appeal.

- Glass and aluminum doors – Durable, secure, and thermally efficient for all building types

- Storefront Systems and Curtain wall – Ideal for hospitals, offices, retail centers, and institutional buildings

- Laminated glass – Enhances safety, sound control, and thermal comfort

- Shower Doors and Shower Slider – Perfect for hotels, condos, and multifamily housing

- Custom mirrors and decorative glass – Adds brightness and elegance to interior designs

All PRL systems comply with ASTM, NFRC, and LEED standards, ensuring high performance for both new construction and renovations.

Why Sioux Falls Developers Trust PRL Glass & Aluminum

Builders in Sioux Falls rely on PRL for precision-made systems, dependable delivery, and expert support tailored to Midwest conditions.

Why South Dakota professionals choose PRL:

✅ Fast, reliable nationwide shipping from U.S. mainland facilities

✅ Custom-engineered systems built for cold climates and high winds

✅ Energy-efficient solutions crucial for year-round temperature variations

✅ Comprehensive design and installation support

Benefits of Glass and Aluminum Systems in Sioux Falls

Glass and aluminum provide long-lasting value and performance across South Dakota’s diverse construction needs.

- Superior Thermal Efficiency – Critical for freezing winters and warm summers

- Noise Reduction – Ideal for busy commercial corridors and expanding residential neighborhoods

- Weather Durability – Withstands snow, wind, hail, and drastic temperature swings

- Modern Architectural Appeal – Suitable for both contemporary and traditional Midwest styles

- Sustainable Materials – Recyclable and LEED-compatible

- Battle Door Capability – Reinforced options protect against break-ins, vandalism, protests, and severe weather events

PRL Glass & Aluminum, your National Supplier

From our location in California, PRL Glass & Aluminum serves South Dakota and all 50 states in the United States.

We offer service in major cities across the country:

✅ Cheyenne

✅ Honolulu

✅ Fargo

Follow us on social media ✅

Stay tuned for news, events, discounts and new products through the different social media channels.